From Wikipedia, the free encyclopedia

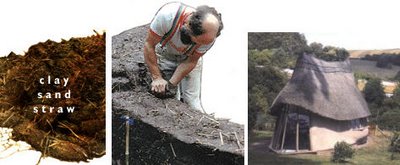

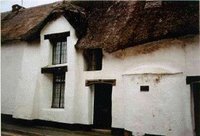

Adobe is a building material composed of water, sandy clay and straw or other organic materials, which is shaped into bricks using wooden frames and dried in the sun. It is similar to cob and mudbrick. Adobe structures are extremely durable and account for the oldest extant buildings on the planet. Adobe buildings also offer significant advantages in hot, dry climates, as they remain cooler as it stores and releases heat very slowly.

The word "adobe" is Spanish and comes from the Arabic "at-tub", the brick, and from the Coptic "tObe". The word may be pronounced ah-doh-beh or uh-doh-bee. Buildings made of sun-dried earth are common in the Middle East, North Africa, and in Spain (usually in the Mudejar style). The method of brickmaking was imported to the Americas in the 16th century by Spaniards.

A distinction is sometimes made between the smaller adobes, which are about the size of ordinary baked bricks, and the larger adobines, some of which are as much as from one to two yards long.

In more modern usage, the term "adobe" has come to mean a style of architecture that is popular in the desert climates of North America, especially in New Mexico. (Compare with stucco).

Composition of adobeAn adobe brick is made of soil mixed with water and an organic material such as straw or animal dung. The soil composition typically contains clay and sand. Straw is useful in binding the brick together and allowing the brick to dry evenly. Dung offers the same advantage and is also added to repel insects.

Adobe bricksBricks are made in an open frame, 25 cm (10 inches) by 36 cm (14 inches) is a reasonable size, but any convenient size is acceptable. The mixture is molded by the frame and removed. After drying a few hours, the bricks are turned on edge to finish drying. Slow drying (shaded) avoids cracking.

The same mixture to make bricks is used for mortar as well as for plaster on interior and exterior walls. Some ancient cultures used concrete for the plaster to protect against rain damage.

The largest structure ever made from adobe (bricks), was the Bam Citadel, which suffered serious damage (up to 80%) by an earthquake on December 26, 2003. Other large adobe structures are the Huaca del Sol in Peru, built using 100 million signed bricks, and the ciudellas of Chan Chan, also in Peru.

Thermal propertiesAn adobe wall can serve as a significant heat reservoir. A south facing (in the Northern Hemisphere) adobe wall may be left uninsulated to moderate heating and cooling. Ideally, it should be thick enough to remain cool on the inside during the heat of the day but thin enough to transfer heat through the wall during the evening. The exterior of such a wall can be covered with glass to increase heat collection. In a passive solar home, such a wall is called a Trombe wall. Adobe has a relatively dense thermal mass, therefore this type of construction is most useful in tropical climates. In temperate climates it is less effective to heat a structure this way due to heat leaching by the ground and walls.

A selective biography

A selective biography Straw Bale

Straw Bale

From Wikipedia, the free encyclopedia

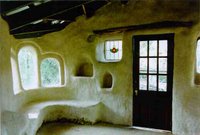

From Wikipedia, the free encyclopedia Modern cob buildings

Modern cob buildings